The Infrared Reflective (IR) pigment color options provide you with cooler colors, unmatched colorfastness along with excellent chemical and weathering resistance. White with TiO2 pigment will have the best solar reflectance, but not always the most practical or desirable when decorative colors are preferred.

When selecting colors other than white, the surface color will absorb light at certain wavelengths and reflect it at others. IR pigment technology allows for the use of beautiful and bold colors, including black tones, to have impactful total solar reflectance (TSR) compared to non-IR conventional pigments.

Understanding The Solar Spectrum

- Ultraviolet (295-400 nm): The UV region starts at 295 nm where the atmospheric cut-off occurs. While UV only accounts for roughly 5% of the sun's energy that reaches the Earth's surface, it is a major contributor to the degradation of coatings.

- Visible (400-700 nm): Roughly 50% of the sun's energy makes up the wavelengths that give us the perception of color.

- Infrared (700-2,500 nm): Forty-five percent of the total solar energy is in the infrared region. Most of the energy in the infrared range is found in the 700-1,200 nm range. Beyond 2,500 nm there is little solar energy. The solar infrared region is different from the infrared energy given off by objects as heat. For most everyday objects, the heat emitted is found at much longer wavelengths and is dependent on an object's black body properties.

For an object in an outdoor environment, the four main mechanisms of reflectivity, emissivity, convection and conduction determine its temperature. Convection is largely dependent on air flow, and conduction depends on how well an object is insulated to prevent heat flows. Reflectivity and emissivity are the factors that can be manipulated.

The Benefits of Selecting IR Pigment

There are numerous reasons why you should choose IR pigments for your outdoor stain or coating project.

- Cooler to the touch

- Less thermal degradation

- Fade resistant

- Excellent chemical resistance

- Excellent heat resistance

- Superior coastal exposure

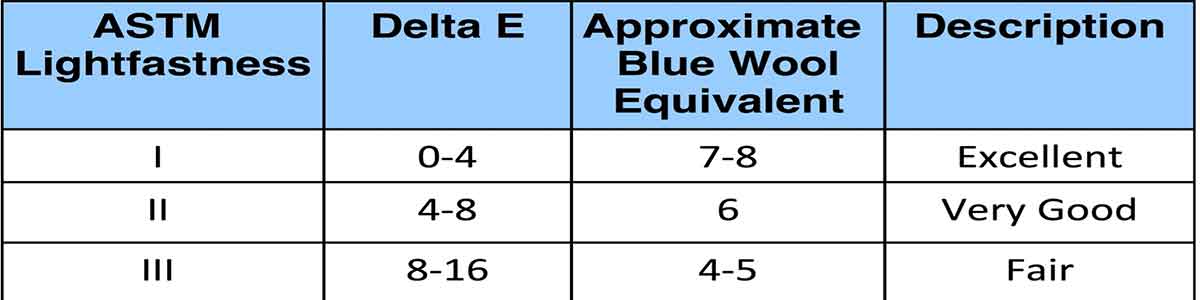

By understanding what happens to color over time when exposed to light and especially sunlight, you begin to explore what your color deterioration level is. The difference becomes clearer when compared to day one baseline or color control to the exposed color. The industry ASTM guide of color differential is measured by using a Delta E measurement. A Delta E comparison over a 25-year period is expected to remain in the Excellent range (ASTM 1). Whereas, with a conventional pigment depending on the pigment colorfast grade will only stay within the ASTM 1 - 3 range for 6 months to 10 years.

ASTM Delta E Rating:

Delta E - Lightfast Ratings:

In summary, the typical expectation is that IR pigments fade resistance is 3x+ more colorfast than conventional pigments and reduces surface temperatures by up to 35°F on darker colors.